Equipment Houses

Oversize Shipment Protection

Salt Storage Sheds

Fire Hydrant Enclosures

Digester Domes

Marine and Coastal Buildings

Natural Gas Odorizer Buildings

Radiation Monitoring Enclosures

Emergency Generator Enclosures

Navigation Equipment Enclosures

Hazardous Area Personnel Buildings

Chemical Material Storage

Open Air Test Sites (OATS)

Hazardous Material Storage

Corrosive Chemical Storage

Radioactive Decontamination Structures

Chlorination and Dechlorination Enclosures

Communication and Telecommunication Equipment Buildings

Washdown Labs

Rooftop structures

Fueling station kiosks

Nonmetallic Test Labs

High Voltage Enclosures

Lift Pump Station Covers

Turbine Rotor Enclosures

Chemical Wash Buildings

Motor Control Centers

Wastewater Treatment

Chemical Processing Structures

Cooling Tower Pump Buildings

Personnel Decontamination Buildings

Radioactive Equipment Storage

Chimney Stack Pollution Monitoring Enclosures

Electromagnetic Compatibility (EMC) Test Buildings

Electrostatic Dissipative (ESD) Clean Rooms

Dehumidification Equipment Buildings

Animal Shelters

Structural Construction

General purpose FRP

Fire Retardant FRP

Insulation (R7, R11, R14, R21, R28)

Equipment mounting panels

NEMA 3R certifications

Knockdown capable

Preassembled

Removable panel options

Removable roof options

Electrical

Load centers and receptacles

Class I, Div. 1 capabilities

Alarms and Sensors

LED lighting options

Damp location wiring solutions

High voltage grounding options

Unistrut integration

Unique application needs

Doors

Grade I – single or double

Grade II – single or double

Integrated windows (security glass)

Panic bar exit device options

Roll-up doors (internal or external drums)

Hatch access

Bulkhead access

Sliding or bifold style options

Nonmetallic options

Mounting

Drop-over

Integrate steel base

Crane or Fork-liftable

Built-in containment reservoirs

Colors

Any Interior and Exterior color option is available

Gloss or Texture finish available

HVAC

Forced or Convective ventilation

Heating options

A/C options

Specialty Needs

Alarms

Sensors

Customer equipment pre-installation

Unique bulk-heads

Unique Configurations

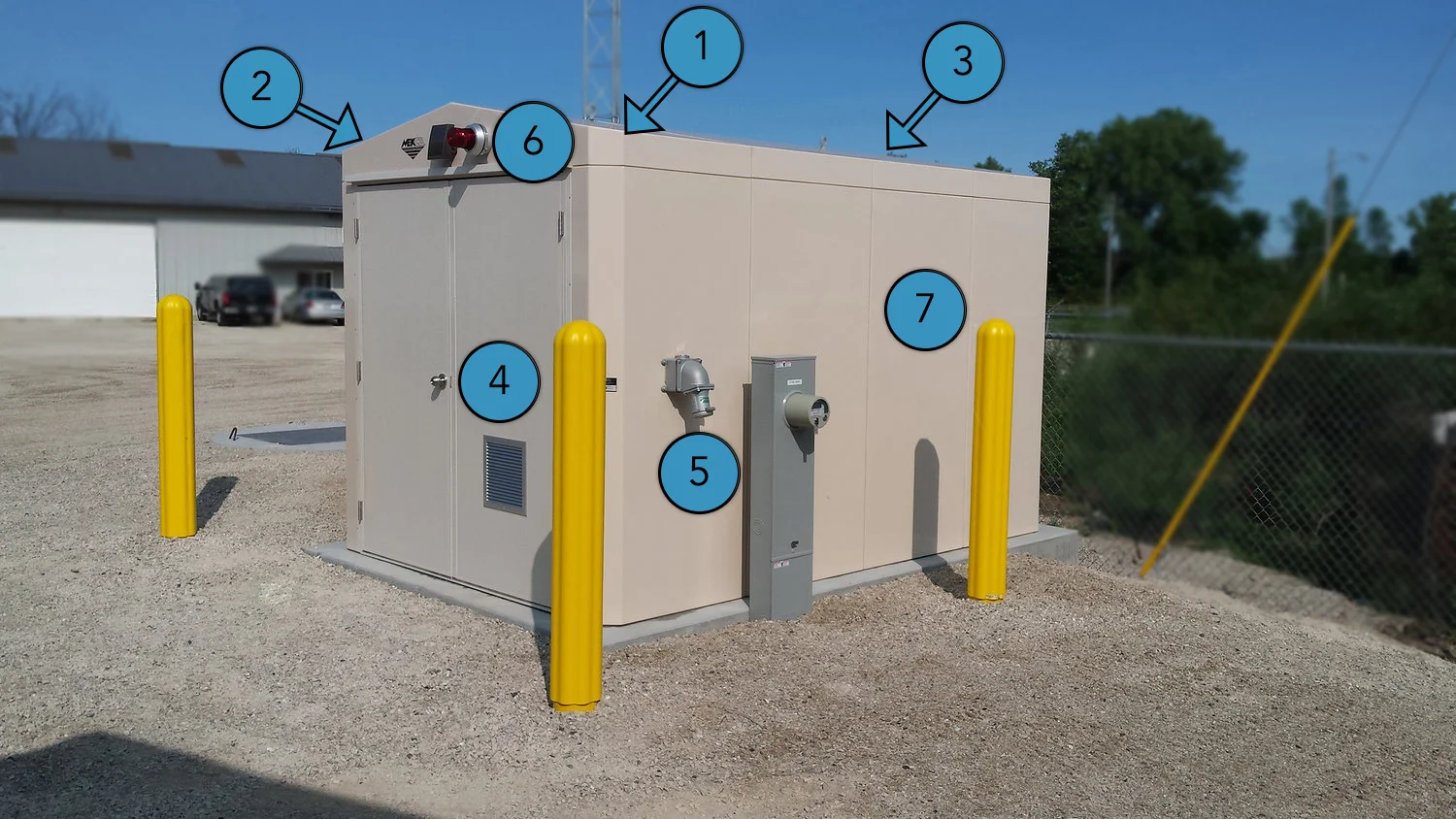

MEKCO® FIBERGLASS BUILDING FEATURES

1. Structurally-cored advanced composite building panels for greater insulation, strength, and stiffness values. Energy efficient space-saving profile.

2. Engineered freestanding roof systems offers high snow capability and absolute reliability in the harshest conditions.

3. Removable lifting eyes for optional placement or easy access to obstructed equipment.

4. Full-access FRP doors with industrial grade hardware and custom ventilation options.

5. Ready-to-power electrical feeds and other systems to streamline your final installation and minimize on-site labor costs.

6. Custom sensors and lighting to ensure that safety measures are at the forefront of design.

7. Custom color options to fit your environment.

About Mekco® Fiberglass Buildings

MEKCO fiberglass buildings have been serving industry since 1976. These buildings can be found in every state of the Union – and well beyond. Many of these buildings have been tested with the worst that Mother Nature can conjure up – from snowstorms to hurricanes and literally everything in between. MEKCO buildings are tough – in every sense of the word.

Because we make our own tooling (in-house) and have more than 200 tools in our collective “library”, MEKCO fiberglass buildings are 100% customizable. Go ahead, toss us a curveball. We take great pride in providing the customer with exactly what they need – nothing more and nothing less.

At MEKCO we pride ourselves in quality and timing. Just because your building is unique doesn’t mean you’ll need to wait months to receive it. Most of our custom buildings are ready to ship within 3-4 weeks of production sign-off. Sometimes even faster. We operate on the premise of lean manufacturing and have a staff and supply chain that believes in being nimble. We look forward to the opportunity to tackle your unique challenge.

- Adam Schneider, President